Orientation & Training Program

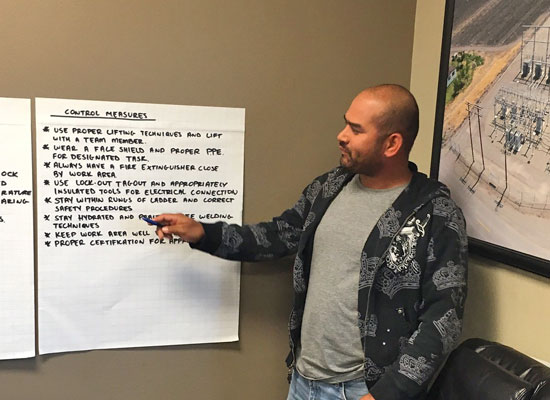

Frontline Safety Training

TTR Substation requires a 2 ½ day Foreman’s Academy training program that focuses on frontline safety management skills.

Mandatory Orientation

All employees attend the OSHA ET&D 10 hour program educating our crews on the hazards and regulations of the civil and electric substation construction industry.

Employee Training Program

All new employees attend the New Employee Orientation and Training classes and any additional specialty training that may be needed for their professional development and/or the specific project needs.

Training Program Courses

At a minimum the following courses will be conducted for the specified groups:

All Employees

New Employee Safety Orientation

- TTR Substation Welcome – Our Core Values, Vision and Safety Culture

- Substance Abuse Program

- PREVENT® – Overview and expectations

- Overview of TTR Safety Program

- Medical/First Aid/CPR/AED Training

- Emergency Response and Emergency Action Plan

- Operation of Motor Vehicles – Safety Expectations

- Hazard Communication and Global Harmonization System

- Fire Prevention

- Incident Investigation Overview

- Heat Illness Prevention

- Personal Protection Equipment – Jobsite Specific Requirements

- Strain/Sprain Prevention

IBEW Members:

All New Employee and Site Specific courses listed above plus:

- Grounding – EPZ (Equal Protection Grounding)

- Job Briefing

- Job Hazard Analysis

- Behavior Based – Line Work Safety Protocols

- Designated Operator Program

- Safety Audit Program

- Clearances/Holds (Including Customer Requirements)

- Safety at Heights

- Fall Rescue Procedures

- Fatigue Management

- Line Tools

Site Specific

All New Employee courses plus:

- Site Specific Safety Plan

- Gold Shovel Excavation Dig-in Safety Program (PG&E Certified)

- Customer Requirements

- Environmental Awareness and Requirements

- Competent Person Excavation

- Trenching & Soil Mechanics

- Quality Program and Requirements

- Fire Prevention and Project Protocols

- Incident Investigation Requirements

- Emergency Action Plan & Response

As Needed:

- Forklift

- Coined/Enclosed Spaces

- Atmospheric Monitors

- Lead/Benzene/H2S/Hazardous Materials

- Asbestos Class III for Building Maintenance

- Lockout/Tagout (LOTO) Training

- Substation Access Protocols

- Signal Person

- Rigging

- Man Lifts

- Jobsite Specialty Equipment

- Specialty Tools

- Flagger Training

- ET&D Best Practices

- OSHA ET&D 10-Hour Program

- OSHA ET&D Supervisory Leadership 20-Hour

- OSHA Construction 10-Hour

- OSHA Construction 30-Hour